Control principle of electronic jacquard machine

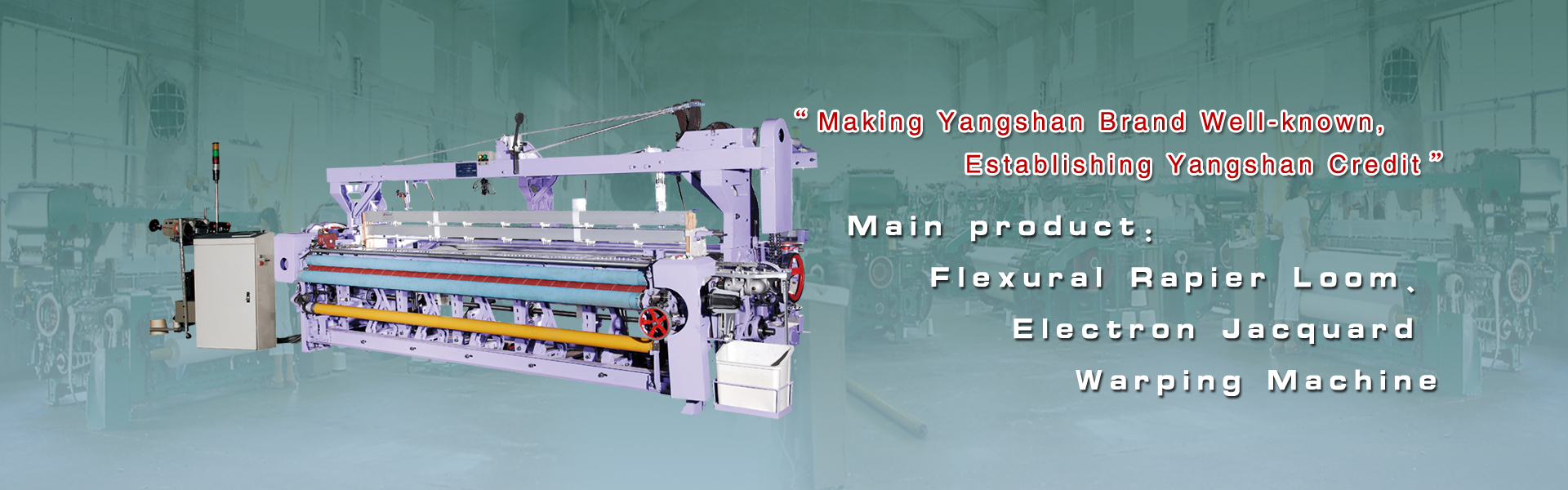

The production of jacquard fabrics has gone through a long and tortuous process from pure manual jacquard to mechanical jacquard to electronic jacquard today. The opening of electronic jacquard machine combines modern micro-electronics technology and electromagnetic and photoelectric technology. With the cooperation of textile CAD system and new mechanical mechanism, high-speed pattern-free jacquard is realized, which greatly improves labor productivity and product quality. The design of electronic jacquard control part takes general purpose micro-computer or industrial computer as the main control body, uses data sources in the form of disk files and network files to meet the requirements of different weaving environments, develops corresponding interface circuits to read jacquard information and generate timing signals, and sends jacquard information to jacquard after driving. Faucet, jacquard control.

International research on electronic jacquard opening mechanism began at the end of World War II. By the 1970s, due to the application and development of large-scale integrated circuits and electronic computers, great progress has been made in the research of electronic jacquard.

In 1983, the first electronic jacquard machine was displayed as a prototype at the Milan Textile Machinery Exhibition. Since then, many jacquard manufacturers have included it in their own development plans. It can be said that since the 1980s, the textile industry has blossomed with hundreds of flowers and schools of thought contending, and the momentum of development is very good.

Compared with other mechanical control jacquard machines, electronic jacquard machines have innovative changes in pattern control. Although different electronic jacquard machines have different structures, they are composed of the following parts in terms of principle:

1, electronic program control device: correctly send out ensemble information, with keyboard, display, printing and other functions.

2. Conversion mechanism between electrical signal and mechanical quantity: generally, electromagnet is used, that is, the synthesizing information from programmable control device is converted into mechanical displacement to realize mechanical control.